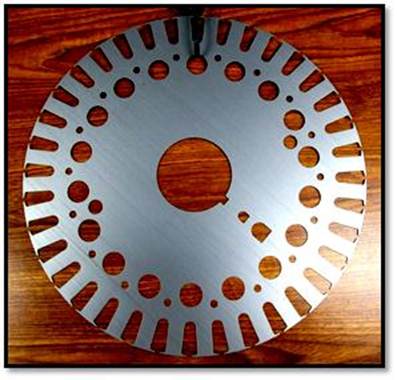

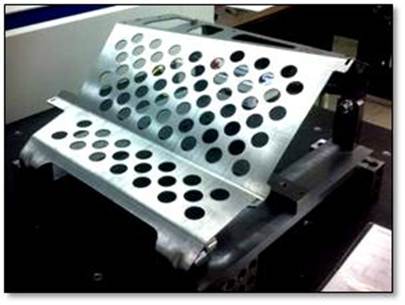

Sheet Metal Fabrication is one of the fundamental forms used in metalworking. The process of manufacturing parts from sheet metal is a straightforward operation in which the metal is shaped or cut through deformation by shearing, punching, drawing, laser cutting, bending, or coining. Production rates are low to moderate and secondary machining is generally not required to produce finished parts within tolerances. This versatile process lends itself to moderate costs, since complex parts can be made in a few operations without the need for expensive tooling. Sheet metal has a high strength-to-weight factor, enabling production of parts that are lightweight and strong. Countless everyday objects are constructed by this process of sheet metal fabrication, welding, assembly and machining. Sheet metal also has applications in chassis, enclosures, medical tables and many other things.

Advantages include: