Converting is the process that specializes in combining raw materials such as polyesters, adhesives, silicone, tapes, foams, plastics, felts, rubbers, liners and thin gauge metals, as well as other materials, to create new products. Typical converting processes are coating, laminating and printing. Coating technologies can include hot melt coating, gravure coating, curtain coating and slot die coating. We specialize in the converting of thin film materials into precision rotary custom die cut components for OEMs large and small.

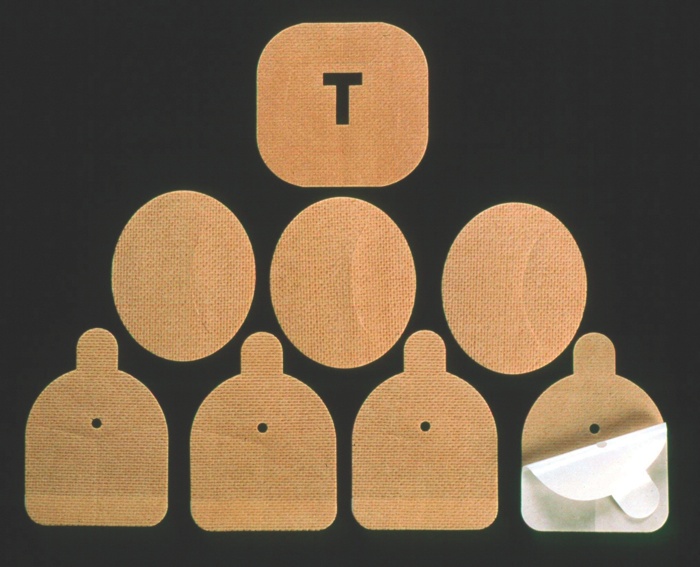

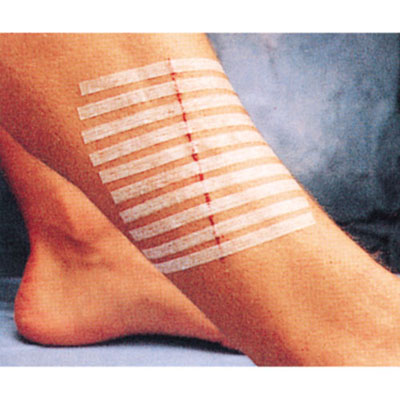

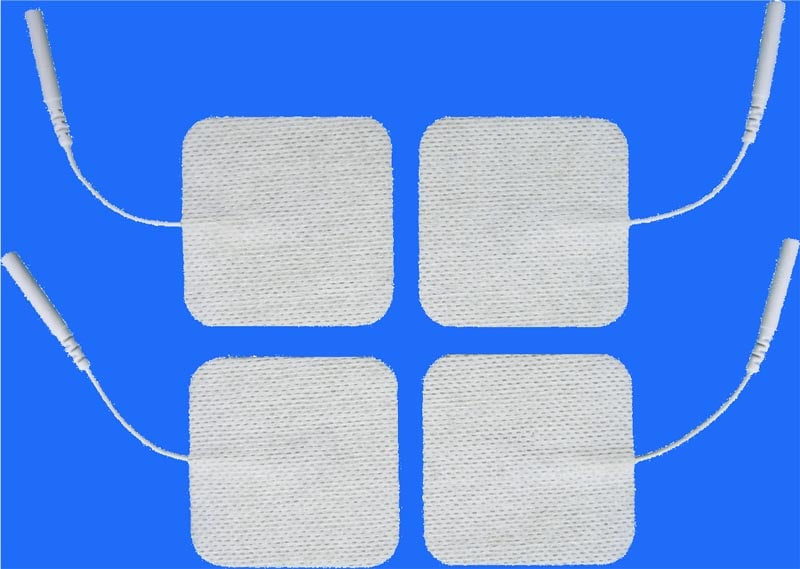

From paint protection for the automotive industry, to circuit board backings for the telecommunications market, to graphic panels for the sign industry, to the production of tracets, Tens patches, and electrodes for the medical market in our ISO 13485 – Class 7 certified clean room, we service a wide variety of markets, from the automotive industry to telecommunications to home décor and stationery industries. We leverage custom state-of-the-art equipment and production processes to provide companies with a total supply-chain resource. From the initial CAD product rendering to the end fulfillment of OEM and retail orders, we can offer a complete supply-chain solution.

We also offer a full line of packaging, warehousing, and distribution options for all your needs.