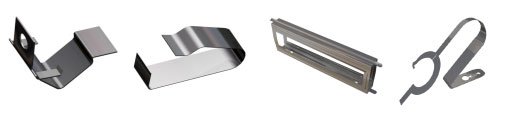

The process of Multi-Slide Metal Stamping is a bit more complex than the other methods of metal stamping. In four-slide or multi- slide stamping the metal or metal wire is approached from multiple sides or angles by the dies, either successively or simultaneously. This produces a final product that is either coiled or bent, depending on the desired result and dies used. Four-slide technology is an excellent process for stamping and forming small, intricate parts with multiple bends from wire or thin strip metal. This process is used to produce springs, clips, brackets, and other materials used in industries such as the construction, industrial and automotive industries.

Proponents of this unique metal forming technology state that many types of parts that are produced on conventional punch presses could be made at a lower cost with less complicated tooling on four-slide machines. With four-slide equipment, the part is formed by four forming tools, which slide into the part intermittently at right angles to each other in one cycle of the machine.