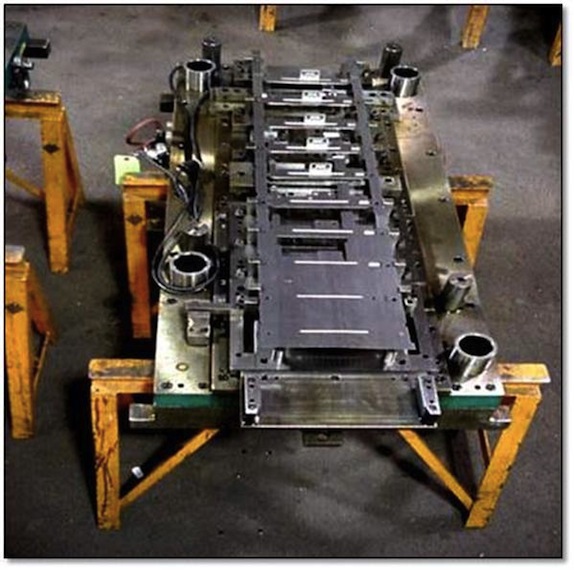

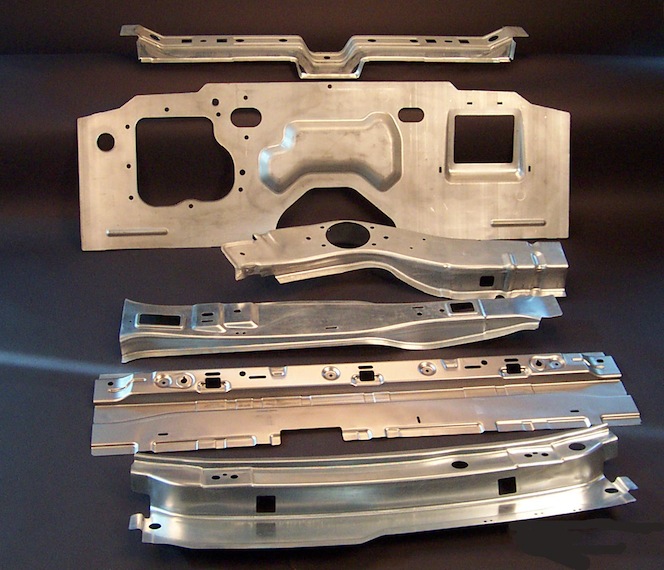

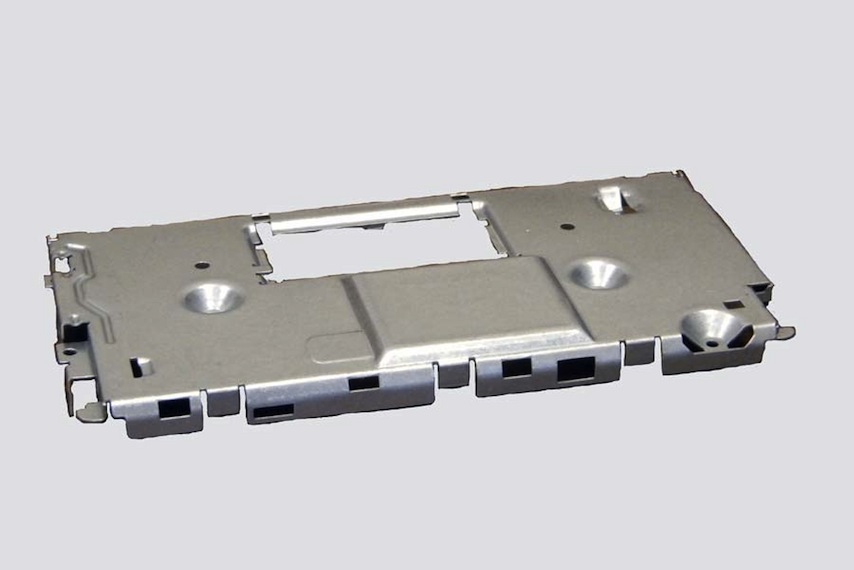

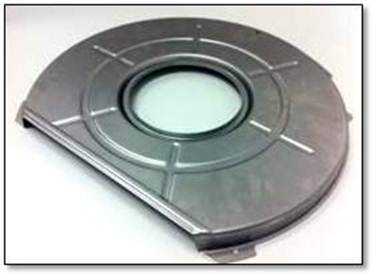

Progressive Die Stamping is a forming process that utilizes a series of stamping stations to perform simultaneous operations as a coil of metal is fed through the machine. The final metal workpiece is developed as the strip of metal is processed through the stamping die. As the metal strip is moved through the drawing process, it is exposed to a series of progressive die stations, each one changing the metal configuration left on the metal by the previous station. Therefore, the metal workpiece is created in a series of stamping stages.

The progressive die stamping process characteristics include: